Electric motor

When an electric motor runs inefficiently it can waste as much as 50% of electrical energy. Dirt, soot, grease, and other contamination can cause electric motors to malfunction. In order to benefit from the full functionality of the motor it must be cleaned regularly. Traditional cleaning by wiping down with solvents is time consuming and requires a stop in production.

By utilizing IceTech dry ice cleaning this downtime can be avoided. Dry ice cleaning allows electric motors to be cleaned much faster than traditional methods. Because of this motors can be cleaned more frequently. When using media blasting on electric motors it is important to consider the delicate nature of the fan. Soda blasting and blasting with walnut shells can be too abrasive. Dry ice cleaning is a non-abrasive cleaning process, so electric motors can be cleaned without damage. Delicate cleaning can be further enhanced by utilizing the IceTech IceSplitter which breaks up the dry ice pellets into a smaller granulate so the impact of the dry ice jet becomes less intensive.

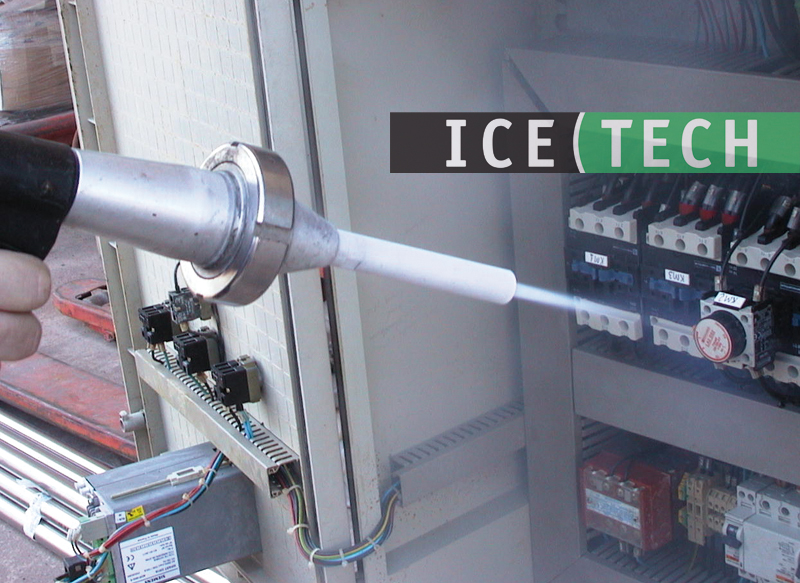

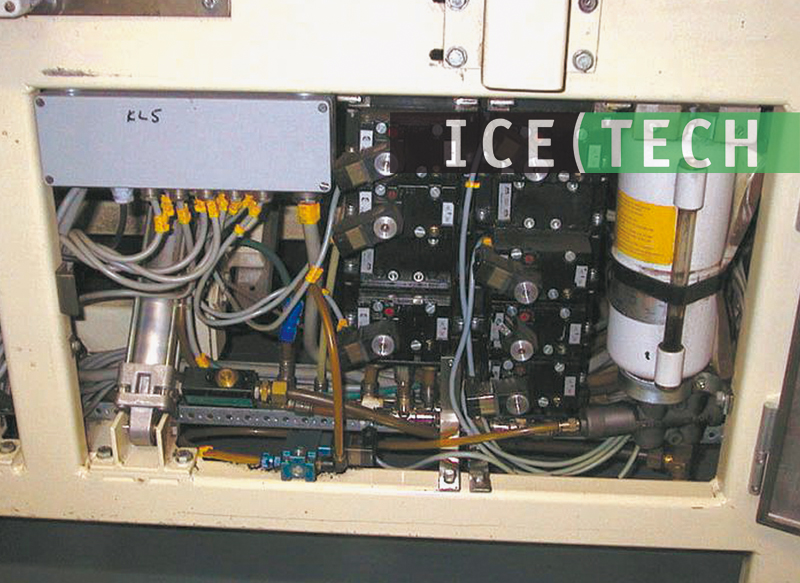

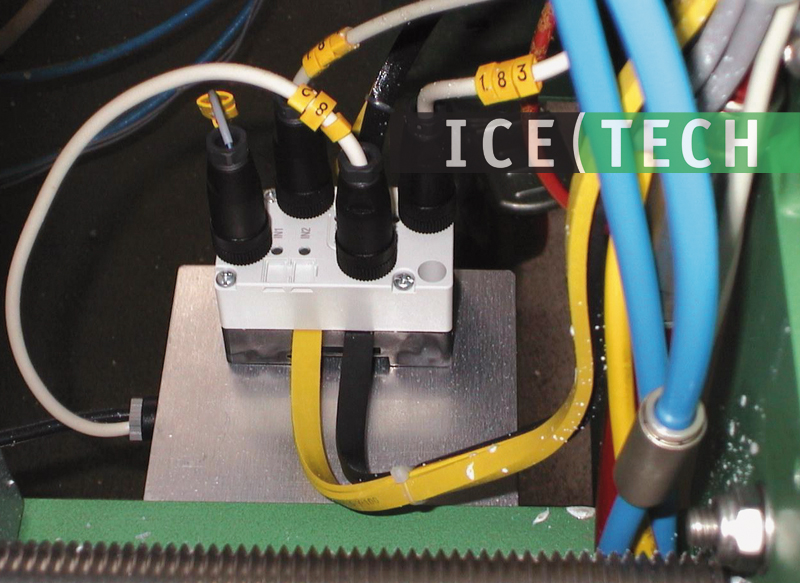

Electrical wiring

Cleaning wires and other electrical components is often overlooked or ignored due to the delicate nature of electrical parts. Refraining from cleaning these parts can lead to machine malfunction, and eventually failure. Being able to clean electrical wires on a regular basis can help improve equipment functionality and prevent failure. IceTech’s dry ice cleaning allows delicate components to be cleaned without damage. As with PC board cleaning, utilizing the IceTech IceSplitter with a flat nozzle is an ideal solution when cleaning wiring.