What is Dry Ice Blasting?

Dry ice blasting, also known as dry ice cleaning, is a revolutionary blasting method that use dry ice pellets (CO₂ in solid form) as a blasting media. The result is a completely dry, non-abrasive cleaning method with no secondary waste. The dry ice pellets vaporize immediately upon contact with the surface being cleaned. Only the coating (contaminants, ect.) that has been removed remains to be disposed of.

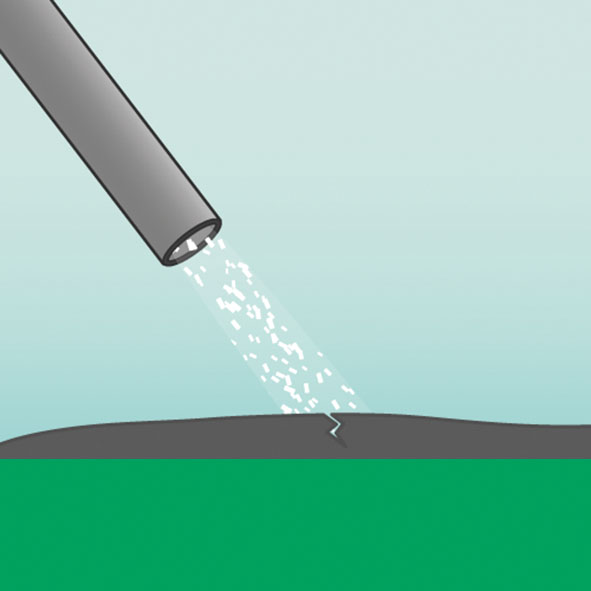

Kinetic Effect

Dry ice pellets are accelerated by compressed air to high velocities thus impacting the contaminant and provoking fractures.

Thermal Effect

The low temperature (-79 C/-110 F) makes the coating brittle, cracks it and loosens it. This allows the dry ice to permeate the coating.

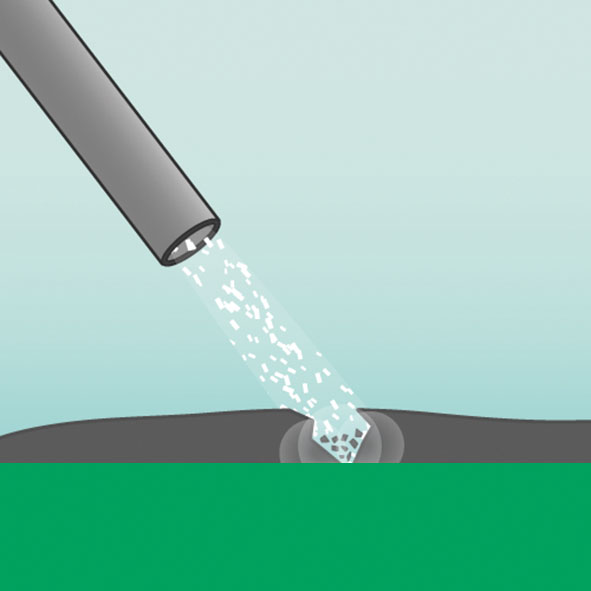

Sublimation Effect

After making impact, the dry ice turns from a solid into a gaseous form (sublimates); expanding its volume by a factor of 700. The expansion acts as an explosion that lifts the contaminant off the surface.

IceTech's dry ice blasting equipment

IceTech’s dry ice cleaning equipment can be used wherever effective and gentle cleaning is required. With dry ice pellets and compressed air, our dry ice blasters can effortlessly clean machines, production equipment, and molds. IceTech’s dry ice blasting equipment can effectively remove contaminants such as oils, greases, glue etc. Dry ice blasting does not leave any cleaning media residue, and equipment can be cleaned without dismantling and costly downtime.

Why is IceTech's Dry Ice Blasting unique?

A non-abrasive, dry process

Dry ice blasting is a non-abrasive cleaning solution where dry ice pellets (CO₂ in solid form) are used as a blasting media. The dry ice pelets vaporize immediately on contact with the surface being cleaning. Dry ice cleaning is a completely dry process, so even delicate electrical equipment and wiring can be cleaned without damage. Since surfaces are treated extremey gently, wear and tear is avoided.

No waste disposal

Dry ice cleaning produces no waste products. Only the contaminant that has been removed remains to be disposed of, and this can usually be swept or vacuumed from the floor.

Environmentally friendly

Dry ice blasting is completely non-toxic and no hazardous chemicals are used. Costs connected with the disposal of blasting media, chemicals or solvents are saved.

Improved productivity

Dry ice blasting often allows the company’s production equipment to be cleaned while in operation. The costly periods of production downtime for dismantling and/or cleaning are reduced.

Fast and effective

The combination of extremely high cleaning speeds and a wide range of nozzles means that even normally inaccessible items can be cleaned rapidly. No blasting media are left on chains and drives, etc.

Lower costs

Dry ice blasting reduces downtime and the resulting costs, by cleaning production equipment quickly and effectivly while in place. Due to the fast cleaning speed production equipment can be cleaned more frequently. This reduces the potential for rejected final products and the associated expense of running an extra cycle.

HOW DO DRY ICE BLASTING MACHINES WORK?

the compressed air stream

the blasting hose by the airflow

Our Products

Dry Ice Blasting Efficiency

IceTech dry ice blasting machines can be used in all production areas. Our machines effectively and gently remove various contaminants off parts, molds, equipment and entire production lines. Here are just some of the industries that have improved their productivity with dry ice blasting.

Plastic & Rubber Industry

With dry ice blasting, molds can be cleaned while they are hot and still in the press. This greatly reduces, and often eliminates, downtime due to cleaning.

Food Industry

Cleaning with dry ice allows food processing equipment to be cleaned without scrubbing or scraping; reducing water waste and damage with equipment.

CONTACT ICETECH

Americas

+ 1 800 337 9423

EMEA

+32 (0) 13 53 95 47

Germany

+49 (0) 6551 9606-0

Asia-Pacific

+81 3 6869 2665